Miniature injection moulding machines BABYPLAST

Babyplast injection moulding machines are the result of long-term research into micro-injection of thermoplastics, ceramics, wax and metal. They have been proven in many applications in the area of healthcare, electrical engineering, automotive and building industries.

- low operating costs

- low space demands

- suitable for all thermoplastic materials

- from single-part to mass production (millions of units)

Babyplast 6/12 a 10/12

horizontal arrangement – maxi-performance for micro-products

The smallest fully hydraulic injection moulding machine proven by thousands of applications in the healthcare, electronic and micro mechanical sectors. It is the result of research and development in the area of micro-injection moulding of thermoplastic materials.

- Suitable for the manufacture of small and microscopic parts.

- Low purchase costs.

- Low costs of the mould production.

- Clamping plates are part of the machine.

- Quality of the produced parts.

- Short time for the mould and material exchange.

- Minimum losses in the change of colour and material.

Babyplast 6/12 P LSR

horizontal arrangement – injection of liquid silicone

Miniature BABYPLAST injection moulding machine for LSR injection reduces purchasing costs for the equipment and the mould. It ensures the highest accuracy due to a reasonably small diameter of the injection pistons (12, 14, 16, 18 mm) and minimum required batch of mixed material in the injection assembly. Movement of the injection unit outside the centre is also possible.

- Injection of liquid silicone.

- Fully hydraulic injection moulding machine with proportional control.

- Maximum input 3 kW.

- Six-zone cooling system.

- Very quiet motor controlled by inverter.

- Can be assembled from 3 mixing systems.

- Maximum safety.

Babyplast 6/10 VP, 6/25 VP

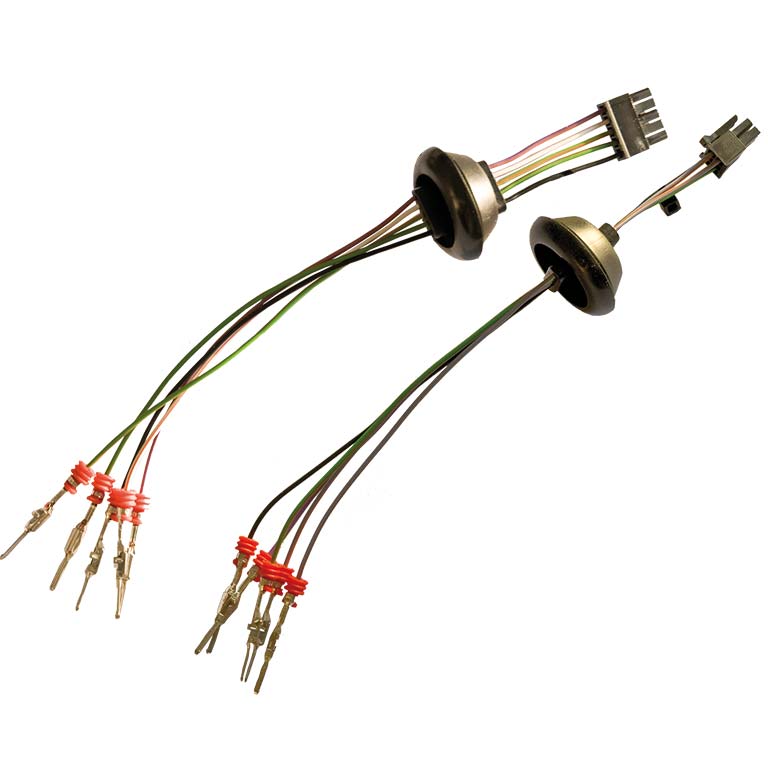

vertical arrangement – specialist in small parts with inserts

Vertical machine with vertical clamp and horizontal injection without draw bars, which can be easily implemented into an automatic production line thanks to the reduced size of the machine base (246x173 mm). It is also available with a rotary table and a V-shaped table, ideal for overmoulding of inserts and cables.

- "V" table for increased efficiency of production.

- Production with a rotary table for incorporation into an automatic line.

- Low costs of the mould production.

- Suitable for inserts.

- No guide rods.

- The "V" table can be used for inserting cables.

UAI - Babyplast I/12 a I/25

supplementary injection unit – a great choice for multi cavity injection moulding

Allows multi cavity injection moulding by a standard injection moulding machine. It is applied directly to the mould or the machine plate horizontally or vertically. It is completely autonomous as regards the hydraulic and electronic systems and is connected with the press by potential-free contacts.

- Two and multi cavity injection.

- Low purchase costs.

- Low space demands.

- Installation directly on the mould (horizontally, vertically, to the fixed or moveable half).

- Installation directly into automatic production lines.

- Installation to any injection moulding machine via EUROMAP 67 interface.

Service of BABYPLAST machines

The care does not end with the sale of the machine. You can rely on professional service directly in your workplace during the warranty period and after its termination.

Materials

Processes all thermoplastic materials, MIM (Metal Injection Moulding):

- CIM (Ceramic Injection Moulding)

- LSR (silicon)

- rubber (NBR)

- Macromelt Holtmelts

- waxes

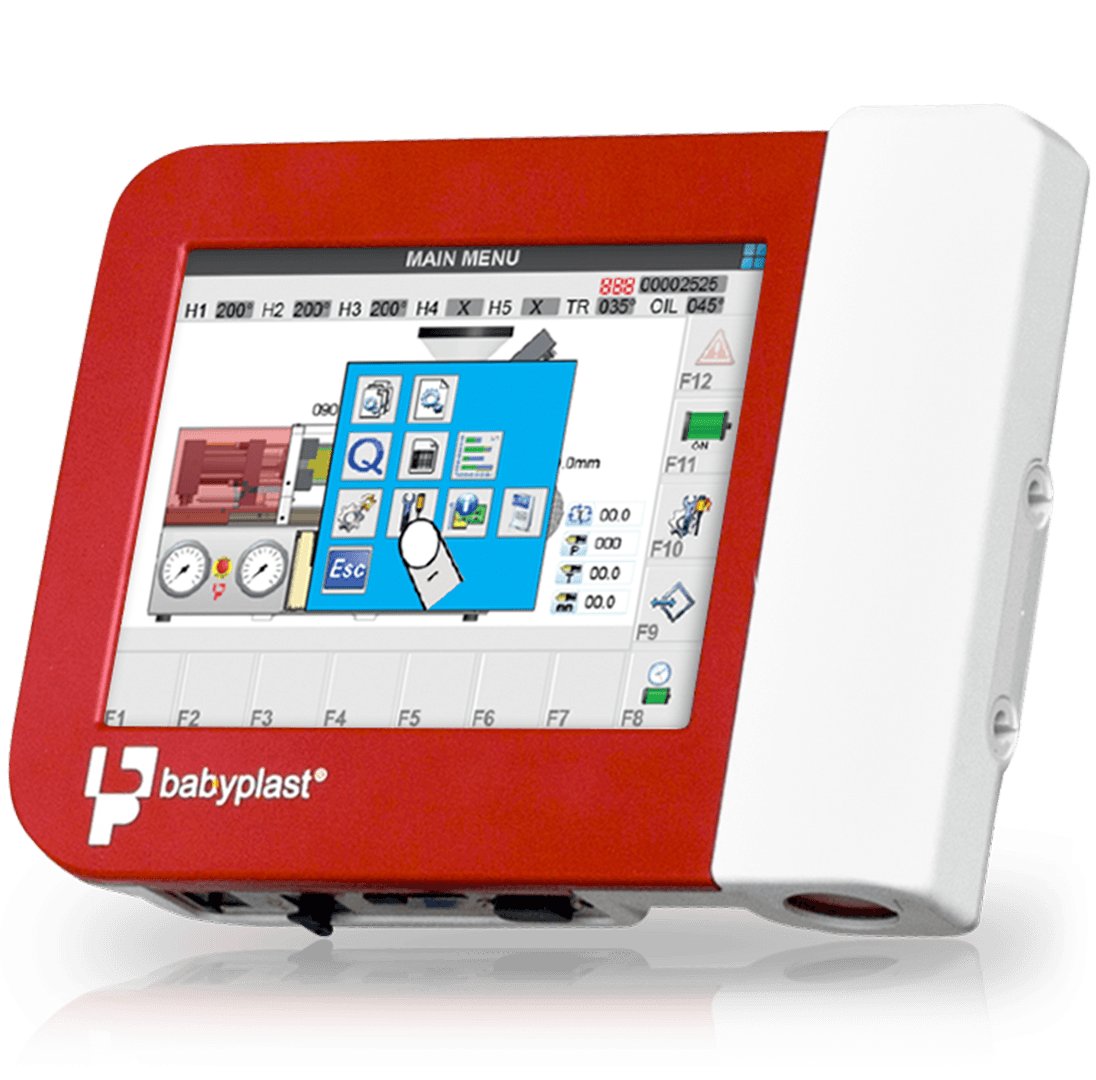

Simple control

The Babyplast machines offer comfortable control thanks to the connectivity and convenience of the control.

- colour touchscreen

- simple control by multi-function keyboard

- creation and storage of programmes

- USB interface

- record of the last 20 cycles

- Ethernet link – by means of TCP

- EUROMAP

Examples of mouldings

Car key

| Material: | PC/ABS |

| Number of cavities: | 1 |

| Weight: | 1 g |

| Total weight: | - |

| Piston size: | 14 mm |

| Cycle time: | 24 s |

Rotor insulation

| Material: | PA |

| Number of cavities: | 1 |

| Weight: | 2,45 g |

| Total weight: | 2,45 g |

| Piston size: | 16 mm |

| Cycle time: | 8,8 s |

Dustpan

| Material: | - |

| Number of cavities: | - |

| Weight: | - |

| Total weight: | - |

| Piston size: | - |

| Cycle time: | - |

Connector

| Material: | PA BERGAMID |

| Number of cavities: | 2 |

| Weight: | 5,8 g |

| Total weight: | 12,4 g |

| Piston size: | 14 mm |

| Cycle time: | 23 s |

Grommet

| Material: | GRANULIT T50 BN00 |

| Number of cavities: | 1 |

| Weight: | 5,1 g |

| Total weight: | - |

| Piston size: | 16 mm |

| Cycle time: | 27,3 s |

Bushing

| Material: | PP + 20GF |

| Number of cavities: | 4 |

| Weight: | 0,4 g |

| Total weight: | 1,6 g |

| Piston size: | 16 mm |

| Cycle time: | 12 s |