PRODUCTION OF PLASTIC PARTS

MODERN PLASTIC MOULDING PLANT

In our modern plastic moulding plant, we put into practice results of the development of plastic parts and the moulds.

Thanks to the complexity of our services, we can thus ensure all phases of the project from the development to the actual delivery of the finished product.

FOCUS OF THE INJECTION MOULDING PLANTFocus of the injection moulding plant

CECHO specializes in the production of small and medium-sized parts, for example for the automotive industry or electrical engineering.

We mostly use the Babyplast injection moulding machines, which are valued for their precision and quality of the final plastic mouldings.

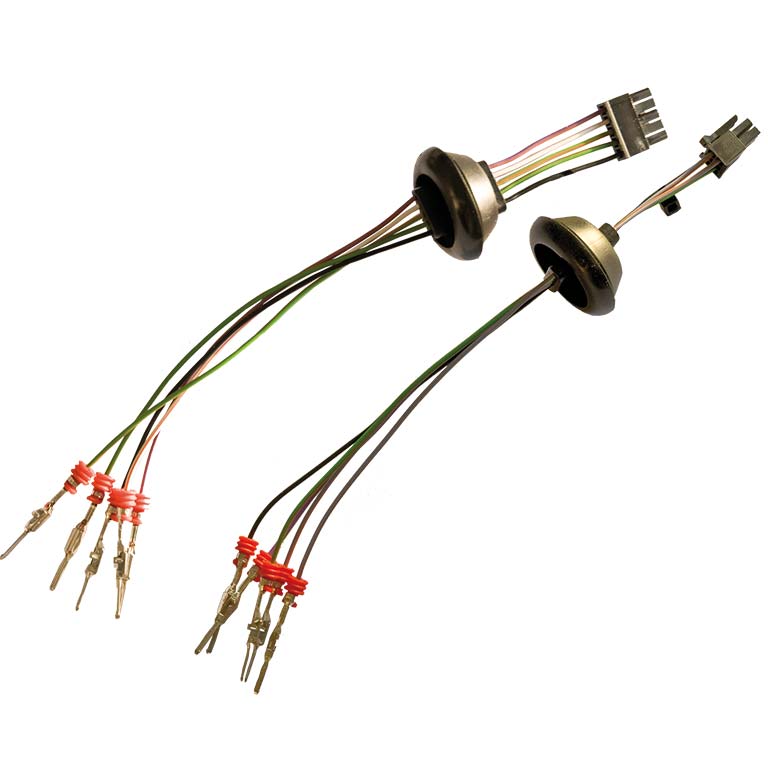

Our horizontal and vertical machines offer wide manufacturing potentialities, such as metal inserts or overmoulding of cables, which we deliver fully completed.

Potentialities of the injection moulding shop

In our production, we use the Arburg, Engel and Babyplast machines.

- production of plastic parts from 0.01 to 392 g

- clamp forces in the range of 6.25–200 t

- single cavity and multi cavity injection

- "overmoulding" and "insertmoulding" technologies

We process all thermoplastic materials (PP, PE, PS, SAN, ABS, PMMA, POM, PA, PBT, PEI, PC, PC+ABS, TPE) and many others according to specific requirements.

Arburg and Engel injection machines

- 10 machines

- clamp force 50 - 200 t

BABYPLAST mini injection moulding machines

- 27 machines

- horizontal, vertical, 2K injection

- clamp force - 10 t

Examples of the mouldings

APPLICATIONS FOR ELECTRICAL ENGINEERING

APPLICATIONS FOR FUEL SYSTEMS

2K TECHNOLOGY

OVERMOULDING OF A MESH

PRODUCTION OF SMALL PARTS BY "MICROINJECTION"